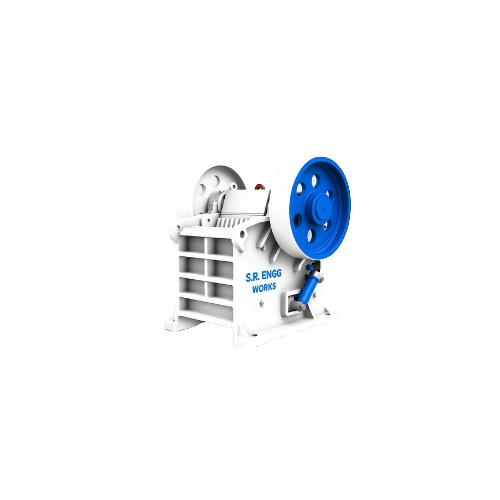

Jaw Crushers

Purpose: Primary crushing of large hard materials like granite, basalt, and limestone.

Available Sizes: 30 TPH to 800 TPH

Applications: Mining operations, road construction aggregates, cement plants, and rock crushing.

Features:

- Heavy-duty structure

- High reduction ratio

- Adjustable Closed Side Setting (CSS)

- Hydraulic toggle systems (optional)

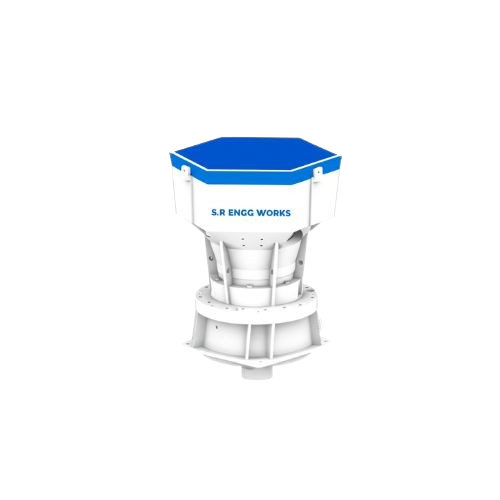

Cone Crushers

Purpose: Secondary and tertiary crushing to produce fine and uniform aggregates.

Available Sizes: 50 TPH to 500 TPH

Applications: Road base production, concrete aggregates, railway ballast.

Features:

- Hydraulic tramp release mechanism

- Automated control systems for settings

- Easy wear liner replacement

- Robust construction for high-demand applications

VSI (Vertical Shaft Impactor) & HSI (Horizontal Shaft Impactor) Crushers

Purpose: Shaping and producing cubical sand and aggregates with excellent particle shape.

Available Sizes: 50 TPH to 300 TPH

Applications: M-Sand manufacturing, plaster sand, high-quality asphalt mixes, concrete production.

Features (VSI):

- Rock-on-rock or rock-on-anvil crushing principle

- High RPM rotors for superior particle shape

- Adjustable feed tubes

Features (HSI):

- High reduction ratio

- Produces well-shaped cubical products

- Suitable for primary, secondary, or tertiary crushing of softer materials

Roller Crushers

Purpose: Fine crushing of medium to soft materials with minimal fines generation.

Available Sizes: 50 TPH to 100 TPH

Applications: Coal, coke, salt, clay, soft limestone, and other friable materials.

Features:

- Low dust and noise emission

- Minimal fines generation

- Smooth or toothed rollers available

- Adjustable roller gap for product size control

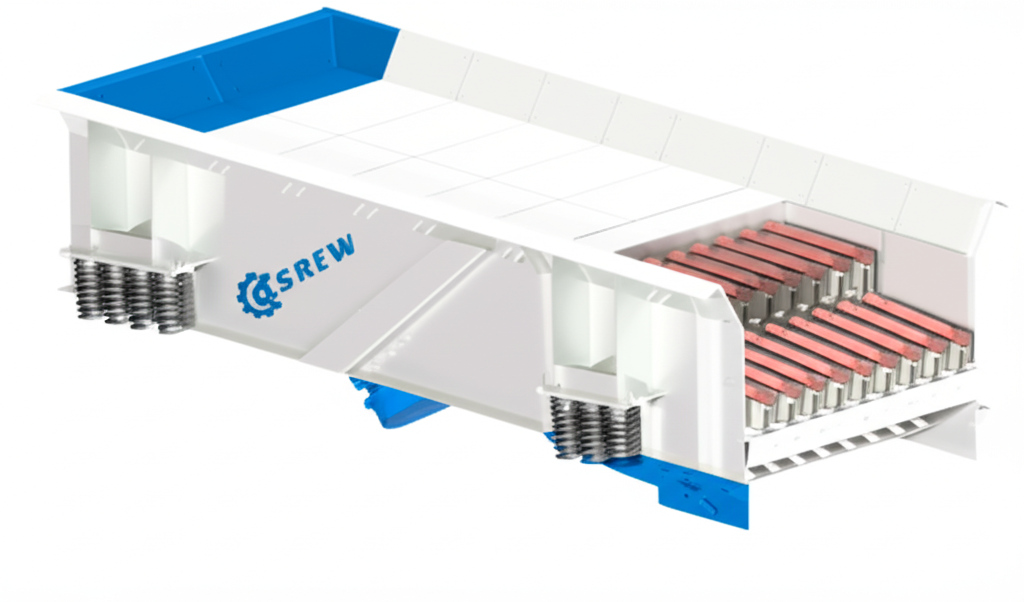

Vibrating Screens

Purpose: Screening and grading materials into multiple precise sizes.

Available Sizes: 2, 3, and 4 Deck configurations; capacity up to 400 TPH

Applications: Aggregate screening, mineral separation, sand classification, recycling plants.

Features:

- High screening efficiency

- Rubber or spring-mounted decks for vibration isolation

- Counterbalance weights for smooth operation

- Easy maintenance and screen mesh replacement

- Robust design for heavy-duty applications

Grizzly Feeders

Purpose: To feed large lumps of material into primary crushers while simultaneously separating fines or smaller particles.

Available Sizes: Capacity from 50 TPH to 400 TPH (Variable size options)

Applications: Quarry primary feeding stations, pre-screening in mining operations, C&D waste processing.

Features:

- Adjustable grizzly bars for varying separation sizes

- Heavy-duty construction for impact resistance

- Powered by robust vibrating motors for consistent feed rate

- Reduces load on primary crusher and improves efficiency

Sand Dryers

Purpose: To reduce the moisture content in sand for various construction or industrial applications.

Available Sizes: 20 TPH to 50 TPH

Applications: Foundries, construction sand, ready-mix concrete plants, silica sand drying, glass manufacturing.

Features:

- LPG/Natural Gas/Diesel-fired options

- Automatic temperature control for consistent drying

- Cyclone separator for dust collection and efficiency

- Rotary drum design for uniform drying

- Heat control PCB for precise temperature management

- Adjustable heat zones (as per project: maintain under 2% moisture)

Silos

Purpose: Storage of dry bulk materials like sand, cement, fly ash, or fine aggregates.

Available Sizes: 15 Tons to 60 Tons capacity

Applications: Batching plants, aggregate storage, recycling facilities, cement plants, road construction sites.

Features:

- Cone bottom for easy material discharge

- Manual or automated discharge gate

- Level indicators (optional)

- Air vent system or dust collector on top

- Robust steel construction

Hoppers

Purpose: Initial loading point for raw material to be processed, ensuring controlled feed to downstream equipment.

Available Sizes: 5 Tons to 30 Tons capacity

Applications: C&D waste recycling intake, raw material feeding for crushers and screens, aggregate plants.

Features:

- Reinforced body for durability

- Vibrator mounted (optional) for smooth material flow

- Grizzly top (optional) for pre-screening large objects

- Designed for easy loading by excavators or loaders

Control Panels

Purpose: Centralized control, monitoring, and automation for all plant equipment, ensuring efficient and safe operation.

Type: PLC (Programmable Logic Controller) or SCADA (Supervisory Control and Data Acquisition) enabled

Applications: Crushing & Screening Plant Automation, Sand Processing Plants, Recycling Units, Safety Control Systems.

Features:

- Variable Frequency Drives (VFDs) for motor speed control

- Temperature control units

- Alarms and safety interlocks

- User-friendly HMI (Human Machine Interface)

- Customizable logic for specific plant requirements

- Robust enclosure for industrial environments

C&D Recycling Units

Purpose: Processing of construction and demolition (C&D) debris into reusable materials like aggregates and sand.

Available Sizes: 30 TPH to 50 TPH

Applications: Urban construction projects, smart city waste handling, demolition site recycling, landfill reduction.

Features:

- Integrated systems including pre-sorting hoppers, trommel screens, and crushers (e.g., Jaw Crusher)

- Metal separator (magnetic) for ferrous material removal

- Air classifiers or density separators (optional) for light waste removal

- Modular design for easy setup and relocation

- Helps comply with environmental norms for waste management

Custom Conveyors & Material Handling Systems

Purpose: Efficient transportation of crushed, screened, or processed material between different machines and stockpiles within a plant.

Available Types:

- Belt Conveyors (Fixed, Mobile, Radial Stackers)

- Inclined Conveyors

- Screw Conveyors (for fine materials)

- Customized transfer points and chutes

Applications: Integral part of any crushing, screening, sand processing, or recycling plant for optimizing material flow.

Features:

- Durable idlers, rollers, and pulleys

- High-quality conveyor belts suitable for abrasive materials

- Reliable geared motors and drive systems

- Covered or open-type options based on application

- Safety features like emergency pull cords and guards

- Designed for specific plant layout and throughput requirements